Forecasting Optimal Performance: Rotamec Partners with National Weather Service

SWEP Plate Heat Exchanger Dismantling, Servicing, and Rebuilding

Rotamec is a leading engineering solutions provider with a specialised site team that offers comprehensive services including plate heat exchangers. Our team recently attended a customer’s site to dismantle, service, and rebuild 4 of their SWEP plate heat exchangers after conducting a site survey. The project involved various tasks, including transportation, isolation, servicing, testing, and finalising the work.

Project Overview

The project aimed to provide efficient maintenance and optimisation of the customer’s 4 heat exchangers packs. The key tasks involved in the project are as follows:

Transporting Tools and Equipment

The Rotamec engineering team carefully transported all the necessary tools and equipment required for the dismantling, servicing, and rebuilding of the plate heat exchangers. They ensured that all equipment was securely loaded onto their vehicle and properly organised for easy access.

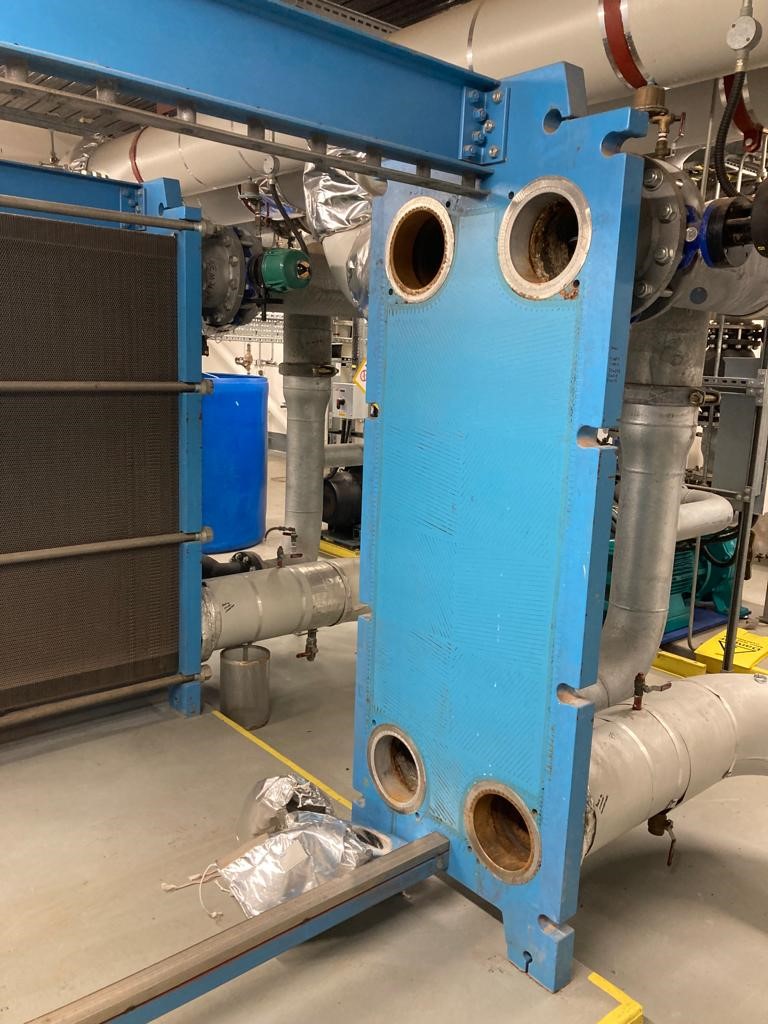

Isolating the System and Drain Down

Upon arrival at the customer’s site, the team collaborated with our facility management partner to isolate the plate heat exchanger system. They followed the necessary safety protocols and completed any local drain down activities to prepare for the servicing work.

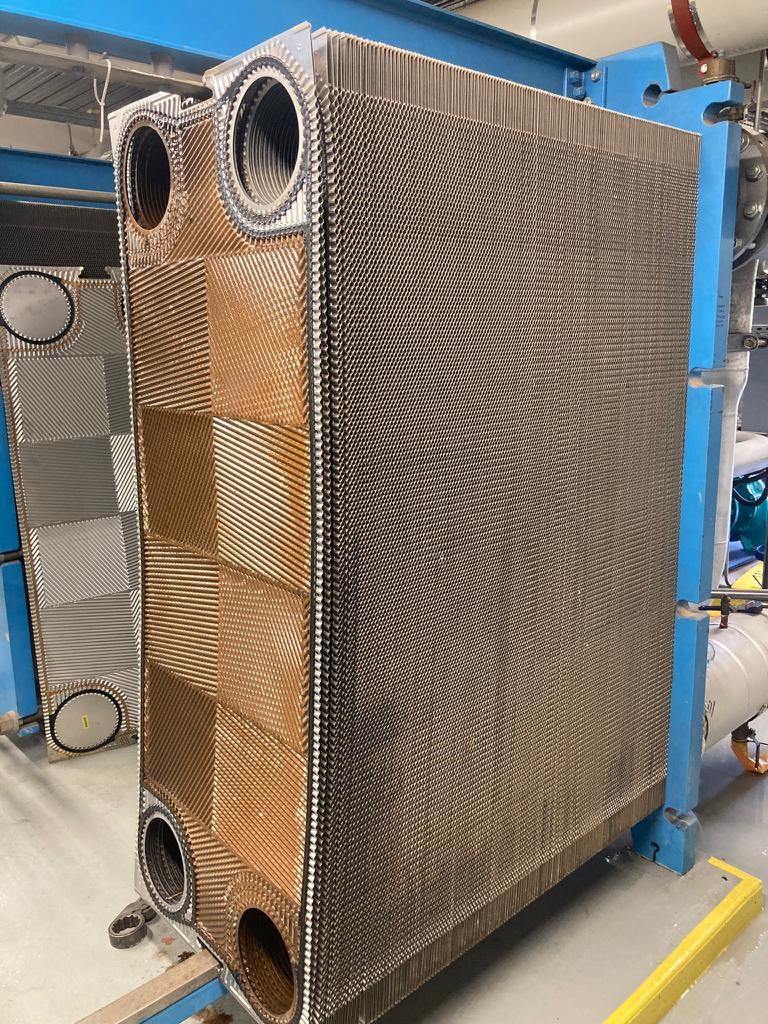

Dismantling and Servicing the Plate Heat Exchangers

The Rotamec team meticulously dismantled the plate heat exchanger, ensuring the safe removal of all components and plate packs, consisting of 270 individual plates. They employed proper handling techniques to prevent damage to the equipment or the surrounding area.

Gasket and Plate Maintenance

The team removed all gaskets from the plates and performed a thorough chemical cleaning process. Additionally, they conducted non-destructive testing (NDT) on all 270 plates contained within each unit to identify and address any potential cracks or defects in the plates, ensuring their optimal performance and longevity.

Rebuilding the Plate Heat Exchangers

After cleaning and testing the plates, the team installed new gaskets to ensure a secure seal and prevent any leakage. The gaskets were carefully selected to meet the specific requirements of the customer’s plate heat exchanger.

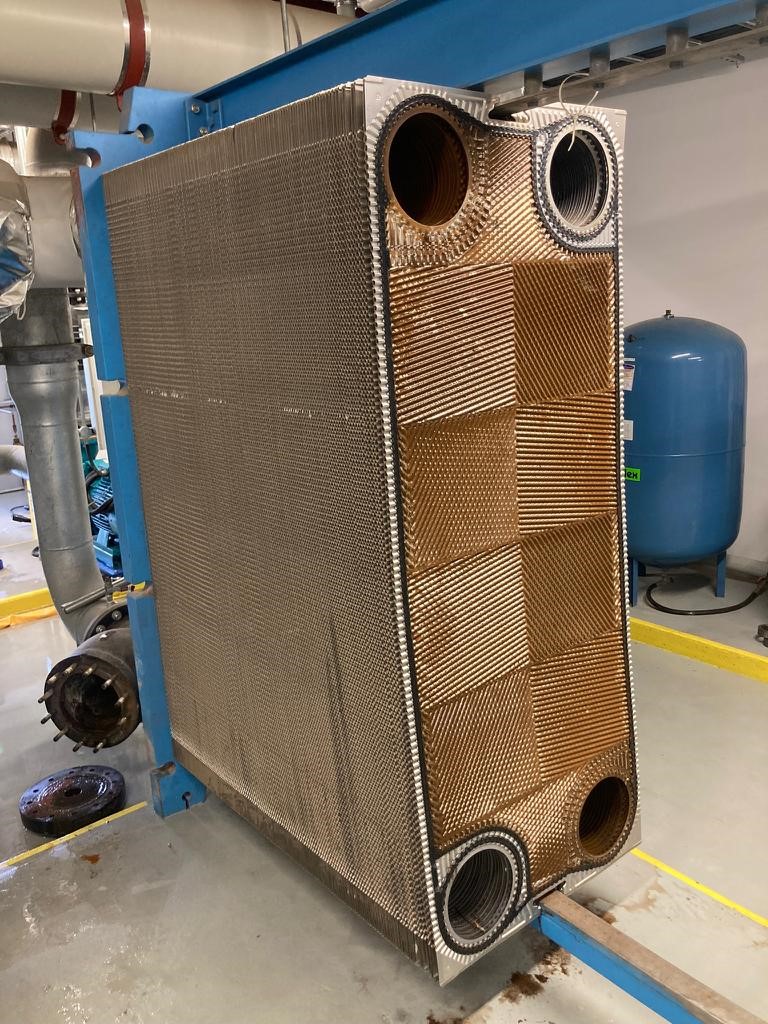

Returning Serviced Plate Pack to Site

The Rotamec team safely returned the serviced plate pack to the customer’s site, ensuring proper packaging and transportation to avoid any damage during transit.

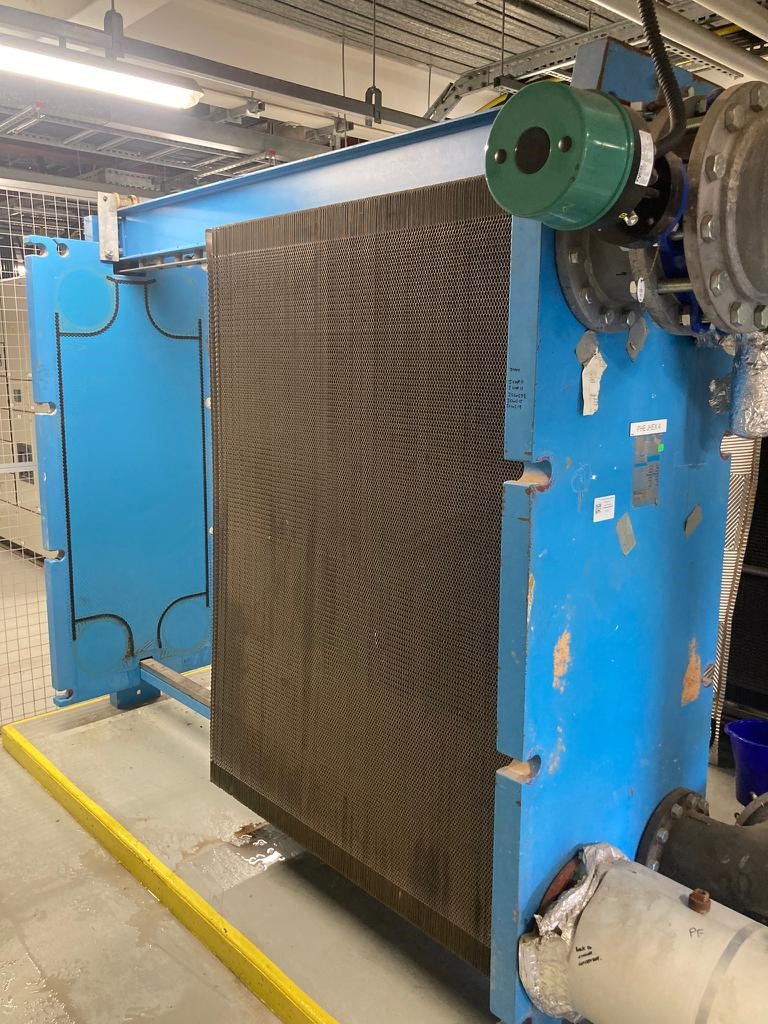

Rebuilding the SWEP Heat Exchanger

With the serviced plate pack ready, the team proceeded to rebuild the SWEP heat exchanger, meticulously reassembling all components, and ensuring proper alignment and tightness.

Testing and Finalisation – Reintroducing Flow and Testing Operation

To validate the effectiveness of the servicing work, the team re-introduced the flow through the heat exchanger and conducted extensive testing to ensure its correct operation. They monitored the heat exchanger for any signs of leaks, pressure irregularities, or performance issues.

Inspection and Testing by the Customer

The Rotamec team invited representatives from the customer to inspect the completed work and verify the functionality and compliance of the serviced plate heat exchanger. Any necessary adjustments or additional tests were performed in collaboration with them to ensure customer satisfaction.

Project Completion

After successfully completing the servicing and testing, the team safely removed all tools and equipment from the site, ensuring that the area was left clean and free of any debris.

The Rotamec engineering team finalised the project by signing off on all required permits and completed documentation. They followed the necessary protocols for signing out at the security checkpoint and departed from the customer’s site.

Rotamec’s engineering team successfully completed the dismantling, servicing, and rebuilding of the customer’s SWEP plate heat exchangers. Their meticulous approach, collaboration with our facilities management customer, and adherence to safety measures ensured a smooth and effective execution of the project. The customer could now benefit from improved heat exchanger performance and increased operational efficiency.