Increasing demand for electric vehicles, energy storage and new devices is placing greater pressure on the global battery supply chain. Battery manufacturers are therefore having to keep pace, making continued uptime at production facilities essential. Enersys, a global leader in stored energy solutions for industrial applications, ensures the uptime of its Newport manufacturing facility by relying on Rotamec, its electro-mechanical service provider.

According to market projections, the lithium-ion battery market is expected to be worth $100 billion USD by 2025[1]. The aforementioned demand for battery products is forecast to deliver a market compound annual growth rate (CAGR) of 14.3% from 2018 to 2025[2]. To maximise the opportunities offered by the move to greener, battery driven technologies, manufacturers need to ensure that uptime is safeguarded as much as possible. This helps to ensure profitability, but from a wider perspective, speeds up the move from traditional fossil fuels to a fully electric future.

Enersys supplies energy storage solutions to the aerospace, defence, material handling, industrial vehicle, leisure vehicle, medical, rail, renewable and nuclear sectors. Its range also features stand by power supply solutions and accessories such as chargers. As a global leader, the effects of increased market demand are felt more keenly by Enersys. This has added pressure to the business, which has meant that there is now no room for downtime.

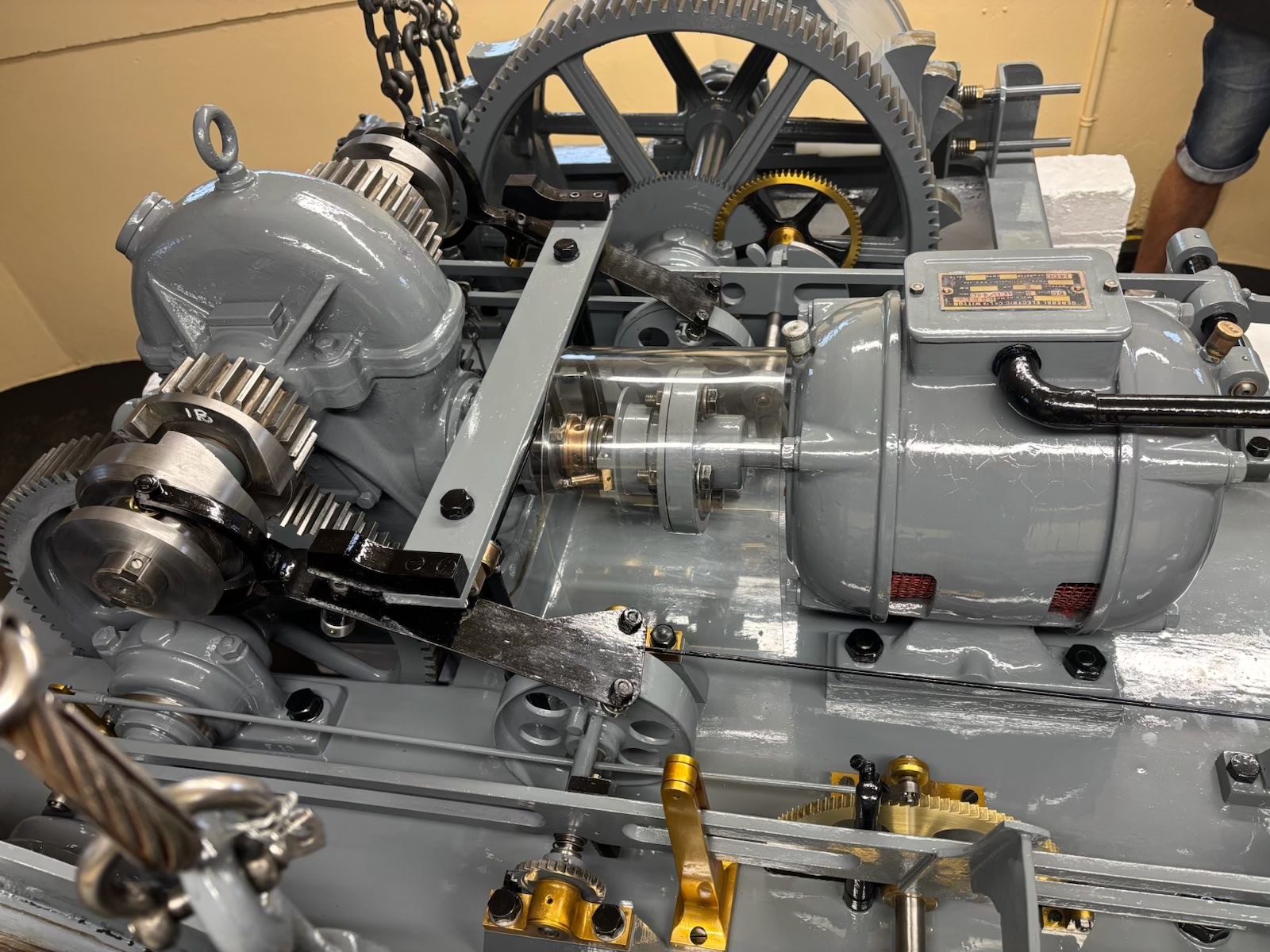

Hugh Williams, Branch Manager at Rotamec Pontypool, explains how his team supports Enersys: “We’re a 24/7 electro-mechanical service provider to the Enersys Newport manufacturing facility. This incorporates maintaining motors, pumps and gearboxes at the site. These devices could be located on the production line itself, in workshops, in offices or in stock. If a reliability issue arises in any of these areas, we must react quickly to either repair or replace equipment which is critical to the facility’s redundancy and uptime.”

Fast reactions to potential issues ensures that manufacturing uptime is properly safeguarded. The close proximity of Rotamec at Pontypool means that service engineers can reach the Newport site quickly, minimising downtime. Localised support matched with an ability to either refurbish or replace equipment also translates to flexible, cost-effective maintenance – a key concern for large manufacturing operations.

Hugh continues: “Enersys operates specialised equipment in production areas, so when a replacement is required, it can pose a challenge. Last year, we were required to trace an American branded motor to fit a specific gearbox. There was no other choice, as the existing frame size was an imperial measurement. We had to inspect the installation, source the correct motor and fit it as quickly as possible with minimal disturbance to ongoing manufacturing operations.

“When the opportunity presents itself, we also uprate equipment. We recently replaced a 45 kW motor with a new unit that offered IE3 efficiency levels. This improved energy efficiency reduces power requirements, improving the carbon footprint of the site.”

Dylan Meredith, Maintenance Supervisor at Enersys, said: “I have been dealing with Rotamec since joining Enersys approximately two and a half years ago. They provide a fast reacting and professional service that goes the extra mile for me. Rotamec are truly a pleasure to work with, and long may it continue.”

Hugh concludes: “Rotamec has been working with Enersys for over 20 years. It’s a partnership which has been secured by fast reactions, reliable solutions and a strong business relationship built up by securing the uptime of key production assets.”