Sourcing spare parts and replacement components from an OEM can take time. When having the right part available makes the difference between critical equipment running or not, waiting simply isn’t an option for operators. Rotamec, a leading electro-mechanical service provider to the engineering sector, is aware of the pressures facing maintenance engineers and provides its customers with access to a dedicated component manufacturing service; which minimises lead times to promote asset uptime.

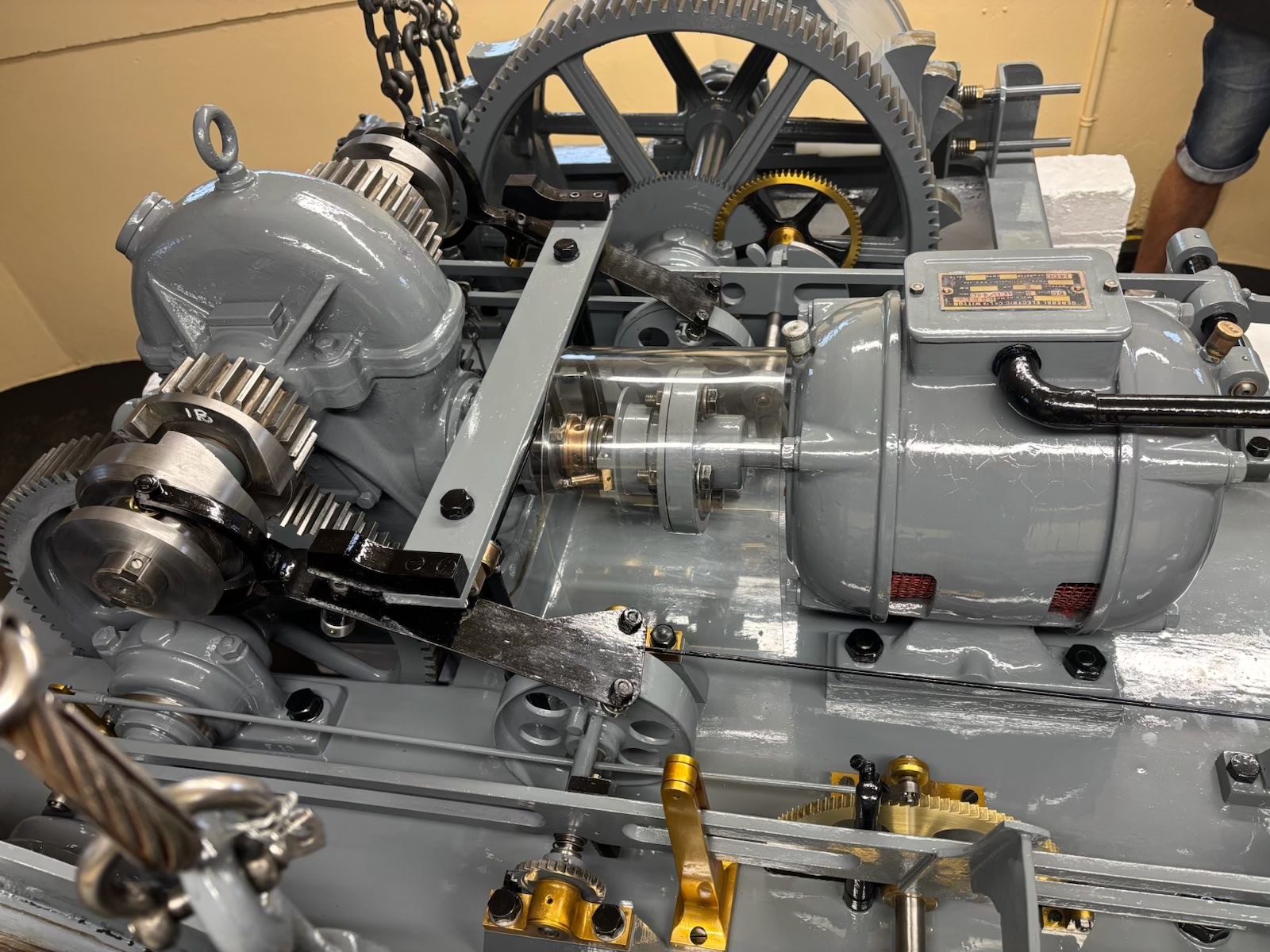

Operating a 24/7 service to help customers keep critical equipment running, Rotamec has invested heavily in CNC and manual tools for a responsive in-house machining and fabrication service. The business can react quickly to provide a single replacement component or a batch run of thousands.

To ensure a short lead time regardless of order quantity, Rotamec operates multiple XYZ CNC lathes, XYZ CNC mills, Colchester manual mills and slotting machines. All are manned by qualified and dedicated engineers. This breadth of equipment and expertise allows the business to offer machining, punching, forming, milling, turning, thread cutting and welding to exacting standards.

Rotamec engineers employ a tailored approach with regards to providing components for each individual order. This ensures that if a component is highly specialised or has peculiar dimensions, an optimum part can be produced regardless. Via reverse engineering and accurate CAD drawings, CNC machines can produce complex parts with virtually zero variation and high repeatability. All CAD drawings are saved on file for future orders.

This capability also allows Rotamec to carry out complete repairs of existing components. Components can be refurbished to provide a cost-effective alternative to replacement, with Rotamec particularly specialising in the repair of critical shaft journals and large conveyor rollers. Obsolete components that may no longer be available can also be reverse engineered, easing the stress of trying to source unsuitable equivalents.

Despite the short lead times, Rotamec ensures that all components that leave the factory are OE quality or higher. All parts are subject to a stringent quality inspection process, which ensures every component is of the optimum specification. This means that speed of delivery is matched by ease of installation and longevity, as each component offers seamless integration with the intended machine.

Ryan Davis, Machine Shop Manager at Rotamec Cheddar Branch, adds: “Our flexible machine capacity, expert engineers and rigorous quality levels mean we can offer the same consistency of service for the manufacture of a single component, a batch production run or a comprehensive component repair. Most of our customers face hurdles when it comes to specifying from an OEM, but we have tailored our service to offer consistently reduced lead times – in many cases down to a matter of hours.”