Proactive checks for a more reliable year ahead

January is traditionally the month for fresh starts and preventative habits—and that mindset applies just as well to industrial assets as it does to personal health. For operations teams, the start of the year is an ideal time to carry out motor, gearbox, and inverter health checks to ensure reliability, efficiency, and reduced risk of unplanned downtime throughout the year.

Why Start the Year with Asset Health Checks?

Rotating and drive equipment often operate continuously under demanding conditions. Minor issues—if left undetected—can escalate into costly failures. A structured health check allows maintenance teams to:

- Identify early signs of wear or degradation

- Extend asset life through timely intervention

- Improve energy efficiency and process stability

- Plan maintenance proactively rather than reactively

Think of it as a full physical for your production line.

Motor Health Checks: The Heart of Your Operation

Electric motors are the workhorses of industrial plants. A comprehensive motor health check typically includes:

- Electrical testing: Insulation resistance, winding condition, and phase balance

- Thermal assessment: Identifying hotspots caused by overload, misalignment, or cooling issues

- Vibration analysis: Detecting bearing wear, imbalance, or mechanical looseness

- Visual inspection: Checking terminal connections, cooling fans, and ingress protection

Early detection of electrical or mechanical faults can prevent catastrophic motor failures and secondary damage to driven equipment.

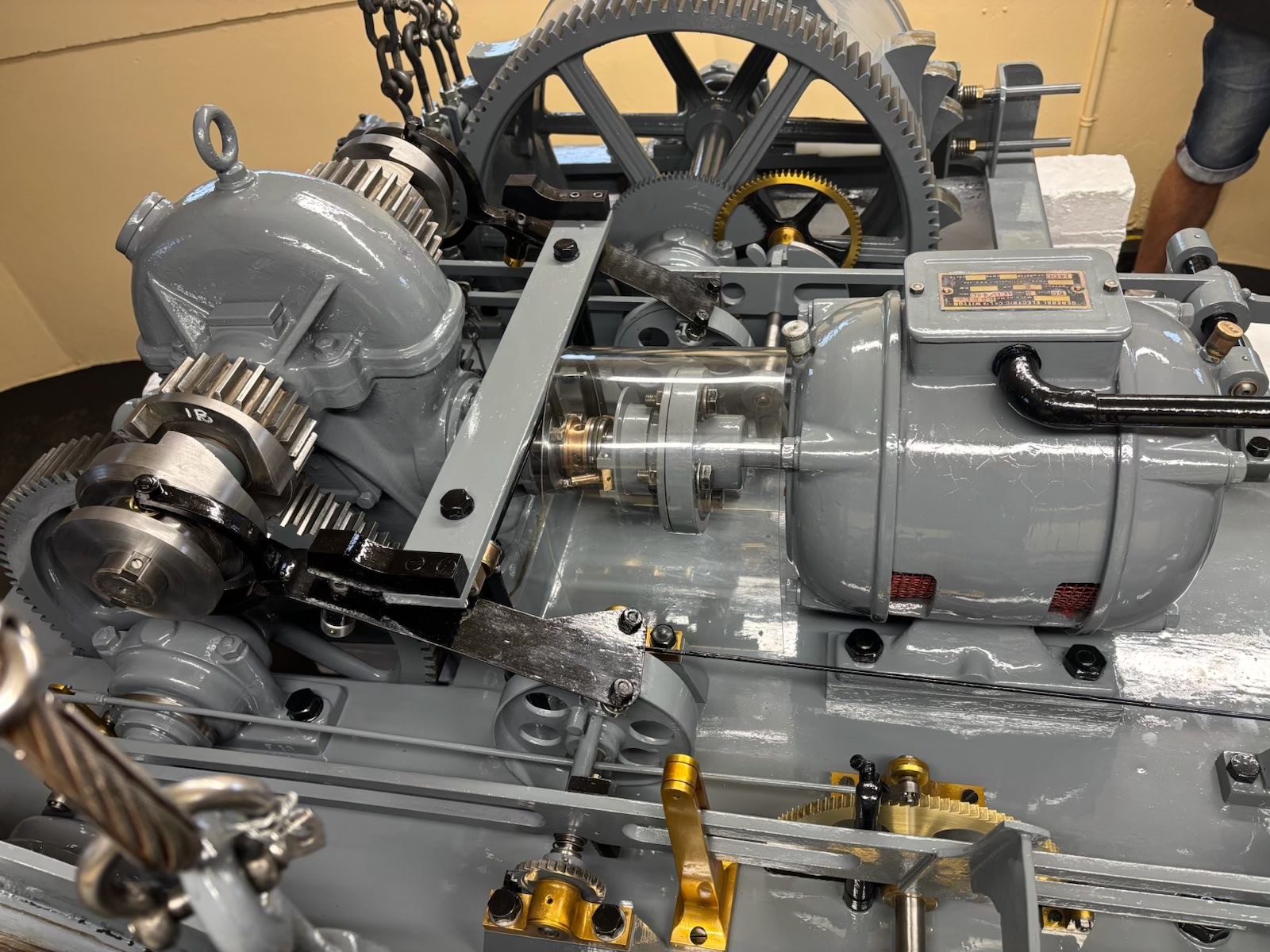

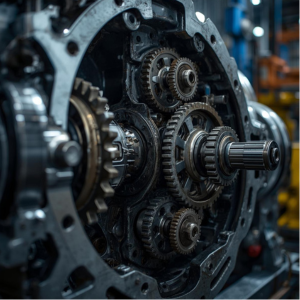

Gearbox Health Checks: Managing Mechanical Stress

Gearboxes translate motor power into usable torque, often under high load and variable conditions. Health checks should focus on:

- Oil condition analysis: Contamination, viscosity breakdown, and metal particles

- Vibration signatures: Early indicators of gear wear or misalignment

- Temperature monitoring: Excess heat often signals lubrication or loading issues

- Seal and housing inspections: Preventing lubricant loss and contamination ingress

Well-maintained gearboxes run quieter, cooler, and more efficiently—directly impacting overall system reliability.

Inverter (VFD) Health Checks: The Nervous System

Inverters and variable frequency drives (VFDs) play a critical role in controlling speed, torque, and energy consumption. Key checks include:

- Capacitor health: One of the most common causes of inverter failure

- Cooling systems: Fans, filters, and airflow paths

- Electrical connections: Loose terminals and signs of overheating

- Fault history review: Identifying recurring operational issues

Proactive inverter assessments reduce nuisance trips, improve process control, and help avoid sudden drive failures.

From Reactive to Predictive Maintenance

Carrying out structured health checks early in the year sets the tone for a predictive maintenance strategy. When combined with trend data and condition monitoring, these checks allow maintenance teams to move away from reactive firefighting and toward data-driven decision-making.

Start the Year Strong

Just as personal health goals are easier to maintain when started early, equipment reliability improves when proactive maintenance becomes routine. A January focus on motor, gearbox, and inverter health checks is a simple but powerful step toward a safer, more efficient, and more resilient operation.

Ready to Get Your Assets in Shape?

If you want expert support in assessing and improving the health of your motors, gearboxes, and inverters, Rotamec can help.

Our specialist teams deliver practical, condition-based health checks that identify risks early, improve reliability, and support a move toward predictive maintenance—without disrupting production.

Contact Rotamec today to discuss a tailored health check programme and start the year with confidence in your critical assets.