In-House Machining Saves Local Packaging Company £10k & Reduces Lead time

We were given an opportunity to supply some specialist Selection Chain to a local Packaging company. The customer had previously purchased these chains from the OEM in France but was keen to explore whether a more cost effective and timely solution could be offered by Rotamec.

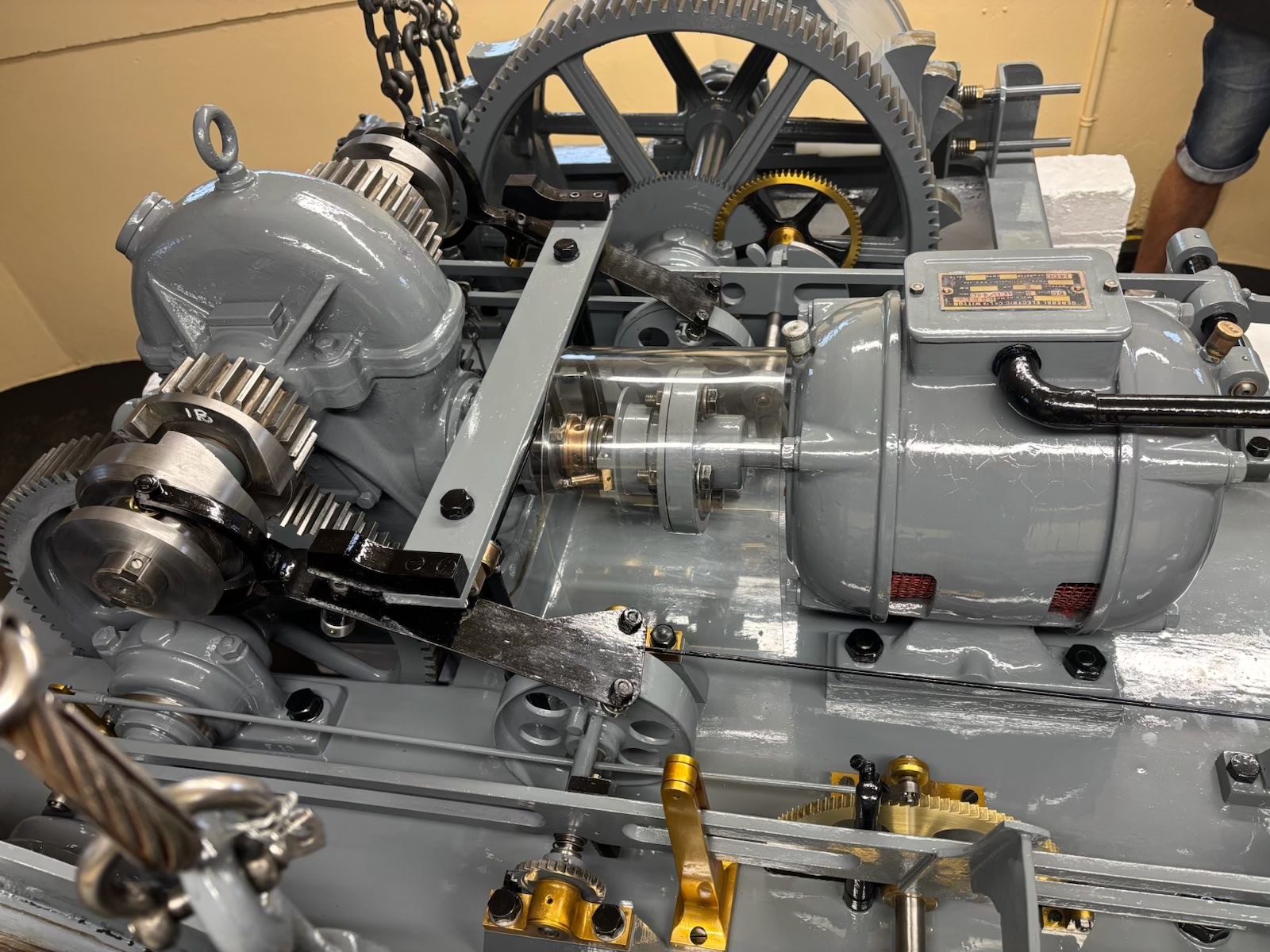

The chain had to be IWIS manufacture as per the end users request and no alternative could be offered on this particular machine. The chains involved standard ¾” pitch British standard base chain but were fitted with various special sliding plates, blocks and shafts plus bearings, fastenings and other ancillary items. The lead times for the complete chains from IWIS proved to be 10 -12 weeks which was unacceptable to the customer as the plant needed to be in service within 8 weeks.

Our machine shop Manager at Cheddar studied the drawings carefully and came up with the solution that would involve Rotamec producing our own CAD drawings and manufacturing all of the required special components in house. Our engineers would then assemble and fit the manufactured parts to the base chain and deliver back to the customer as two complete chain assemblies

The entire project from start to finish came to £25k which resulted in a saving of over £10k to the customer as well as reduced lead times against the OEM. This is a great example of thinking outside the box and getting around the problem of extended lead times from the original manufacturer enabling the Rotamec team to provide the best cost effective Engineering Solution once more!

Rotamec understand our Packaging Customers requirements and have been a key supplier to many Packaging Companies across the South.

Our Skilled Engineers coupled with a Comprehensive Test Facility including in house balancing ensure our repairs are superior. We pride ourselves on our long term relationship with our Packaging Customers. To find out how Rotamec can support your business ring our dedicated team.