When a 21.5 tonne, custom designed gearbox required overhaul, completing the task within a 10-day period was vital. Production at a large steel mill depends on the gearbox, and if the scheduled maintenance couldn’t be completed in time, costs in downtime would be extremely high.

Steel production at one of the UK’s largest steel manufacturing facilities depends on a 21.5 tonne, custom-designed gearbox. Subject to massive stresses, the gearbox requires periodic maintenance to prevent breakdown, but without the gear reducer, the plant’s primary mill cannot operate. Full gearbox overhaul was required within a strict 10-day factory shutdown to avoid production downtime, which would cost the plant tens of thousands of pounds per day.

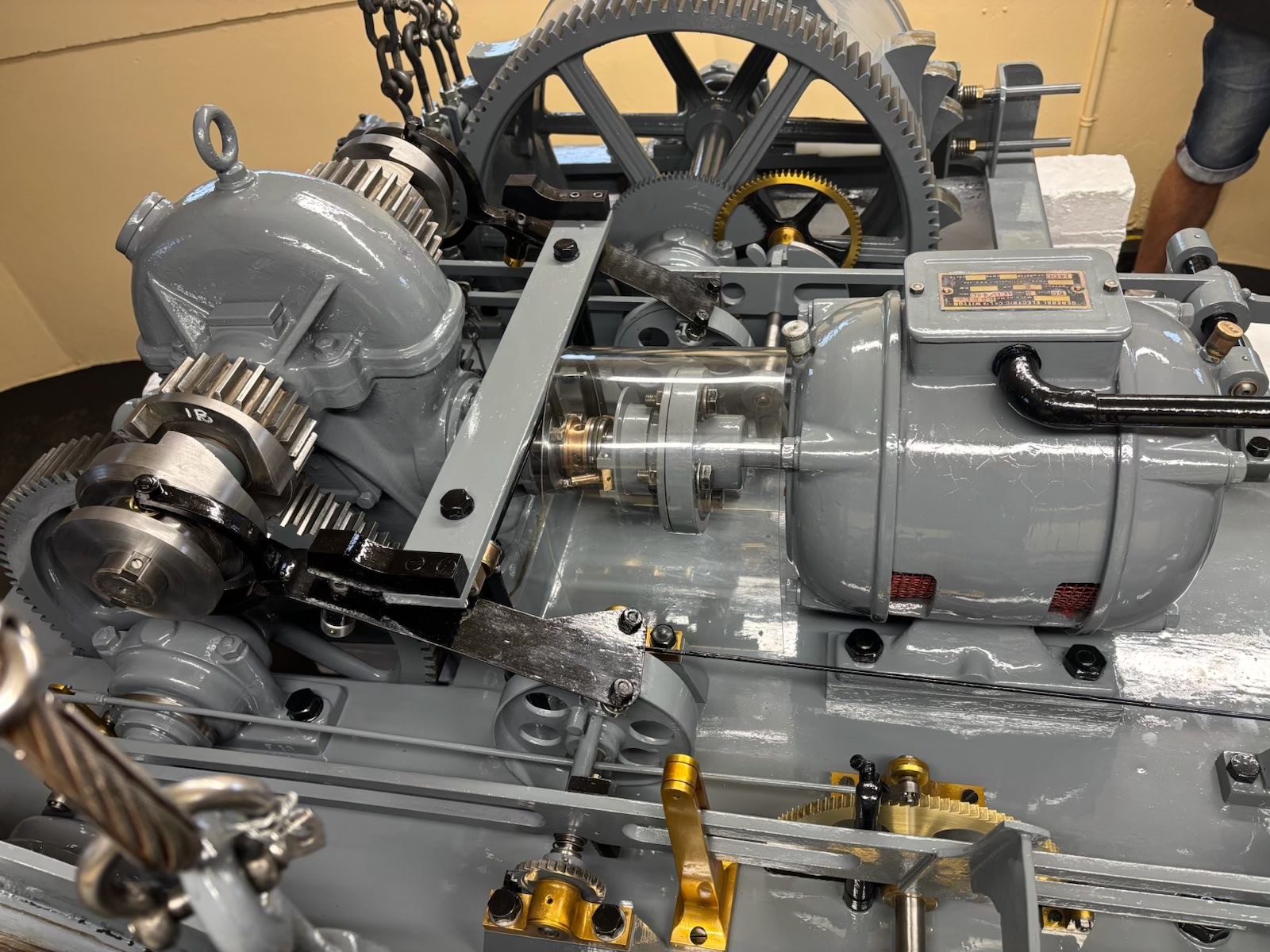

The specialised gearbox is required to control the speed of the rollers within the steel plant’s section mill. The rollers compress the steel, enabling the mill to produce up to 80,000 tonnes per hour of section and merchant bar. The power required to drive the rollers is high, and when a steel bar enters the rollers, this can subject the transmission to high torque extremes. Within these conditions, the gearbox can suffer from issues such as tooth wear, distress to bearings, as well as stress and damage to shafts.

Fast overhaul required

As a result of the stress of the conditions, the gearbox requires periodic overhaul, including inspection, and testing. This ensures the performance and efficiency of operation, and considering the high value of the large, custom gearbox, maintenance intervals optimise its service life. Most importantly for the steel plant, comprehensive overhaul identifies and resolves engineering challenges that would cause unplanned breakdowns over time. Potential downtime costs would also be compounded by a break in contractual supply obligations and reputational damage.

However, because of the integral role of the gearbox to production, overhaul has to be carefully planned and timed to precision. Any delay in the scheduled maintenance will therefore result in downtime. It was a challenge for the steel plant to identify a mechanical repair specialist that could take on this scale of project, even more so when it had to be completed, from collection to reinstallation, within a strict 10-day window to fit a scheduled factory shut-down. Rotamec, the rotating mechanical equipment specialist, took on the task.

Overhaul

Rotamec arranged collection and HGV transport of the 21.5 tonne gearbox to its service centre, fully resourced to handle large-scale equipment maintenance and repair. First, the unit had to be completely disassembled and cleaned to enable a comprehensive inspection.

Each of the five gear lines were removed, and during this stage the extent of wear to the hollow spindles of the fourth and fifth lines became evident. Pitting and corrosion in the hub bore of the fourth line required replacement of the spindle unit. Meanwhile, when attempting to remove the fifth line, it was stuck fast, and hydraulic rams were required to remove the splined spindle shaft. It was identified that ingress of water mixed with grease had caused extensive damage to the hub with heavy pitting corrosion inside the bore. This meant that the hub shaft and spindle receiver assembly also required replacement.

Under the heavy weight and stress of the motor and coupling to the steel mill’s roller, housing bores and gear cases can become misaligned. Therefore, bearing diameters were inspected and measured, with precision adjustments made as required to ensure exacting tolerances. With the bearings removed and the gears cleaned, technicians also performed a series of non-destructive tests to ensure the correct form and integrity of the gears. Under the high load of the rollers, surface distress to the gear teeth can occur, however the structure of the components and their performance under test was robust.

All remaining components were cleaned, the bearings were replaced with new units, and the coupling shroud seal was also replaced. With all gearbox unit fixing studs tightened to the correct tolerance, full overhaul of the gearbox was complete, and the unit was ready for loading onto the customer’s transport.

Completed within 10 days

Reinstalled in optimum condition, the 21.5 tonne custom gearbox will provide the steel manufacturer’s section mill with several years of reliable operation before its next overhaul is required. Crucially for the steel plant, as well as its customers awaiting supply, the overhaul was completed within the 10-day window. This enabled the facility to maintain maximum production capacity with no downtime.

“It was imperative that the overhaul was completed within the timeframe. Failure to achieve this would have prevented production, costing the plant a significant sum. Delayed orders would also impact the plant’s customers, damaging a reputation of trust,” says Paul Pearce, Sales Director, Rotamec. “Importantly, the comprehensive overhaul will ensure efficient and reliable operation of the transmission at the steel mill for years to come, maximising manufacturing quality and productivity.”