Rotamec were recently called to attend to a failed motor on a Belgian scallop trawler. After 30 years of providing the motive power behind the trawler’s capstans and winches, operating in a very tough environment, the 140kw DC motor had seen better days and needed urgent repairs.

However it had been built into the trawler when it was constructed, buried below decks amongst a lot of other equipment making its removal a tough task for the Rotamec team who were called to attend the trawler in Plymouth.

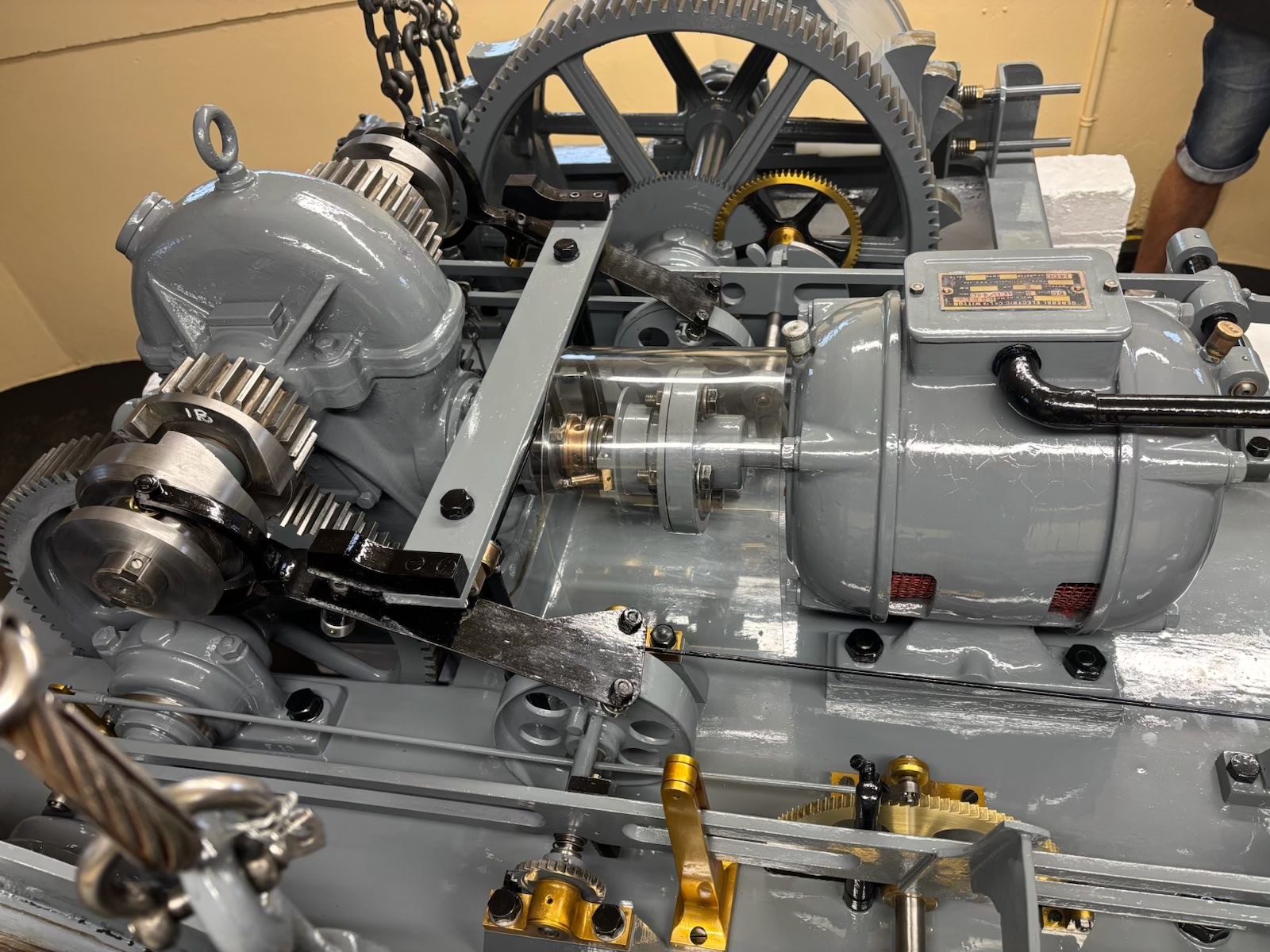

Working in a very confined space the team managed to remove the 30 year old nuts and bolts and eventually manoeuvred the motor onto the trawler’s deck before hoisting it ashore and loading it onto Rotamec’s own transport. Once back at the Rotamec’ HQ in Cheddar the DC motor was stripped and cleaned, the armature was washed, skimmed and undercut, the field coils and interpoles were re-leaded, the brush gear renewed and new bearings fitted.

The motor was then subject to significant testing, before being shipped back to Plymouth to be reinstalled. The reinstallation was also a challenge as it involved the re-commissioning of the trawler’s electrical systems. However the Rotamec team had the motor operational only 72 hours after being called in therefore ensuring that the trawler’s time in harbour was minimised.