Vacuum Pumps

Industrial Vacuum Pump Specialists

Pump and Blower Solutions

The Rotamec Group provides professional vacuum pump repair, servicing, and supply for industrial and manufacturing operations across the UK and beyond. With decades of engineering experience, we support critical vacuum systems to keep production running efficiently, safely, and reliably.

We specialise in the repair, overhaul, maintenance, and supply of vacuum pumps and systems from leading manufacturers including Elmo Rietschle, Becker, Busch, DVP, Orion, Edwards, HP, PD, Leybold, Gardener Denver and Welch

Vacuum Pump Repair Services

Our vacuum pump repair services are designed to restore performance, extend equipment lifespan, and minimise unplanned downtime. All repairs are carried out by experienced engineers using OEM-quality components and industry-approved procedures.

Our repair capabilities include:

-

Mechanical and electrical fault diagnosis

-

Complete vacuum pump strip-downs and rebuilds

-

Bearing replacement and shaft repairs

-

Seal, gasket, and vane replacement

-

Motor testing, rewinds, and replacements

-

Performance testing and certification

We repair oil-lubricated, dry-running, claw, rotary vane, side channel blower, and liquid ring vacuum pumps.

Vacuum Pump Servicing

- Planned preventative maintenance (PPM)

- On-site vacuum pump servicing

- Oil changes, filter replacement, and inspections

- Condition monitoring and performance checks

- Emergency breakdown support

Get Expert Vacuum Pump Support

If you require vacuum pump repair, servicing, maintenance, or supply, contact Rotamec Group today. Our engineers are ready to assess your system and provide a reliable, cost-effective solution.

Call us today or request a quote to speak with a vacuum pump specialist.

Vacuum Pump Supply & Replacement

- New vacuum pumps from leading manufacturers

- Fully reconditioned vacuum pumps

- Like-for-like replacements and upgrades

- System design and vacuum pump selection

- Spare parts and consumables

Our Products

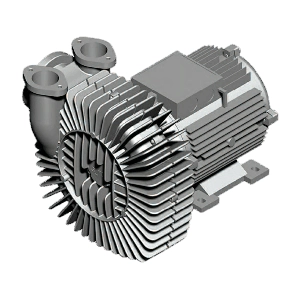

G-BH1 Vacuum Pumps

Volume flow50 to 2,450 m³/h29.4 to 1,441.2 cfm

These are reliable, low-maintenance and durable vacuum pump and can be used for many applications in mechanical engineering.

When used with a frequency converter the performance of the G-BH1 pumps and compressors can be increased considerably.

* Suitable for gas temperatures of up to 200°C

* Enhanced cooling of intake air

* Lower operation and energy costs

* Free from wear

* Low noise level due to acoustic engineering

* Pulsation free

* Not sensitive to dust and fluff

* Worldwide use due to 50 / 60 Hz voltage range motors

* Optional frequency converter

Our Products

G-BH2 Vacuum Pumps

Volume flow330 to 850 m³/hr194.1 to 500 cfm

The series G-BH2 machines are equipped with efficiency class 1 – (EFF1) motors as standard, which also feature multi-frequency and wide voltage range coils permitting use throughout the world.

* New dimensions for side channel technology: vacuum to 780 mbar (abs.) And pressure to 1,000 mbar (abs.)

* Efficiency class 1 quality motors

* Unbeatable reliability and sturdiness

* Worldwide use due to wide voltage range motors

* Extremely quiet in operation; noise levels reduced by up to 50% due to acoustic engineering

* Not sensitive to dust and fluff

* Low operating and energy costs

* 40,000 operating hours

Our Products

G-BH8 Vacuum Pumps

Volume flow100 to 950 m³/h

The new G-BH8 vacuum pumps and compressors have set totally new standards for this technology.

Side channel blowers can typically be found inside larger machines or installations. The available space is limited. To address this issue Elmo have developed the G-BH8. These side channel blowers weigh 65% less and need 40% less space that standard blowers.

* 65% less weight at 40% less space requirements

* Low life cycle costs

* High efficiency

* Low noise

* 20,000 operating hours

* Speed control available

* Virtually maintenance free

* Pulsation free

* Worldwide use