Not many people know that water treatment relies in part on a technology as old as the ancient Greeks. Archimedean screw pumps are still one of the most efficient ways to pump effluent water over short heads, which makes them vital to keep water flowing in treatment facilities. A motor failure on such an important piece of equipment can greatly disrupt operation. One water treatment works in the South West approached Rotamec with exactly this problem, with all repairs requiring completion within 24 hours.

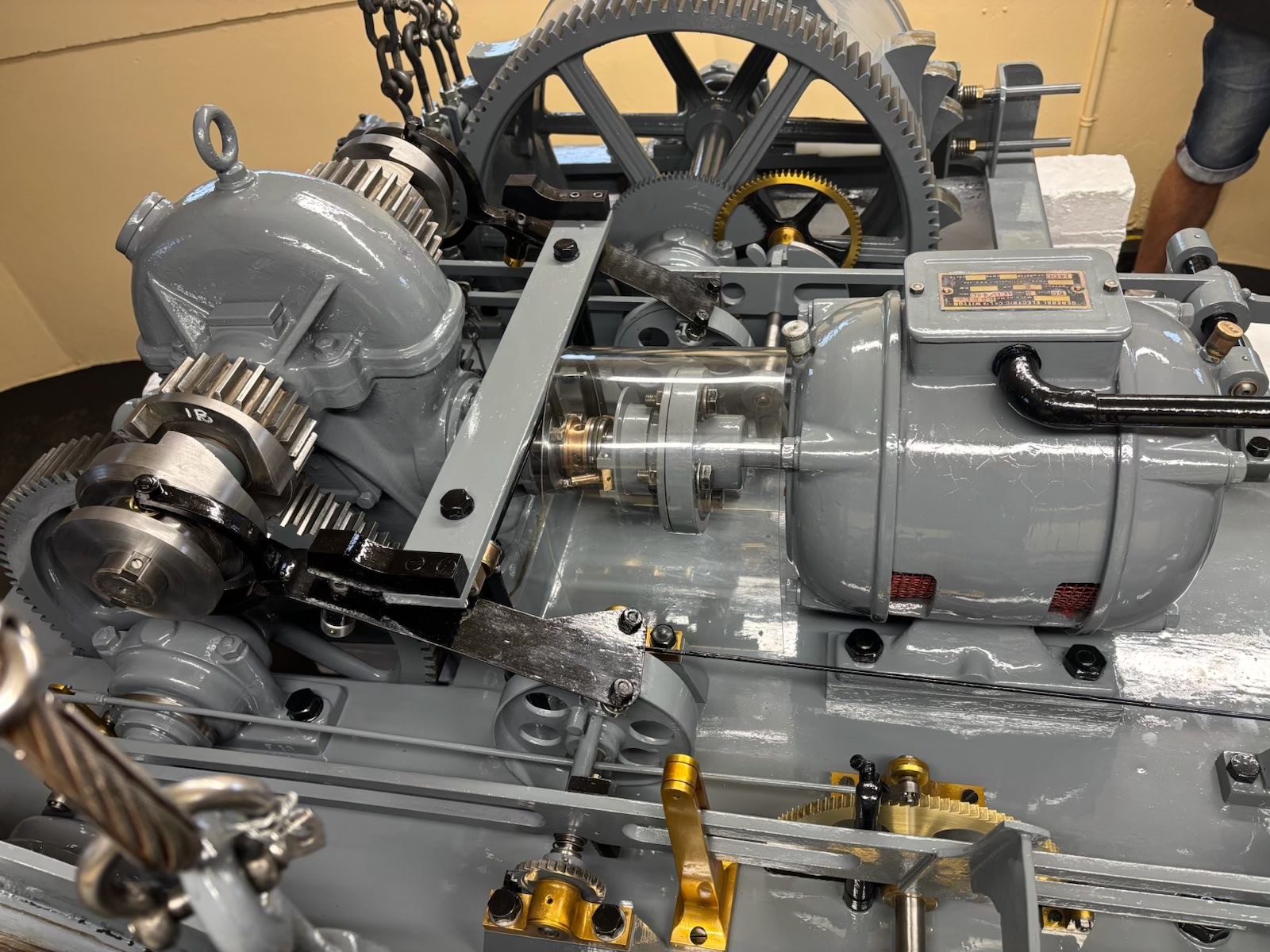

Problems with the motor driving the Archimedes screw pump became apparent after it failed a vibration test. The failure of the substantial 300kW motor left only one other operational screw pump at the installation. With each pump able to move over 10,000 litres of water per second, the failure greatly reduced pumping capacity. Facility managers for the site were quickly on the phone to Rotamec, which offers a 24/7 electromechanical repair service to operators in the water sector and other industries. The motor required stripping, a full inspection, repair and re-installation.

Without the motor, the screw pump would be out of operation. Any extended period of downtime places increased pressure on other pumps at the facility to meet duty requirements, possibly posing further reliability issues as these additional assets work overtime to meet capacity. Worst case, the pump being down for a long time could cause water to back up in the sewage system, placing further strain on the facility. As a result, completing the repair work within 24 hours was of the utmost importance.

Alan Brooks, Manager at Rotamec’s Cheddar Branch recalls the project: “We carry out emergency repair work for multiple water authorities in the UK, so we’re well aware of how important a fast turnaround is. Facility managers organised delivery of the motor to our workshop, and we started out by carrying out a thorough inspection.

“What was immediately apparent was that the end shields bolted to the ends of the motor had failed and would require replacement. These shields are positioned between the bearing and the rotor, preventing the bearing from dropping down the shaft and damaging the rotor. To compound the issue, the bearings in the motor had also failed and would need replacing.”

Sourcing new end shields can take months, which under the time constraints, wasn’t an option. Luckily, Rotamec operates its own in-house machining capability, which combines modern machinery and highly experienced engineers to provide quality replacement components that exactly match original specifications. Rotamec was able to reverse engineer the end shields based on the dimensions and design of the original parts. This allowed each end plate to be reproduced quickly and quality tested within the demanding timeframe. New bearings were also sourced quickly, which ensured the repair was carried out fast.

Once reassembled and tested, the motor was delivered back to the water treatment facility. With the motor installed by site engineers, Rotamec’s on-site team carried out a laser alignment to ensure the continued reliability of the installation. Thanks to the fast turnaround, the Archimedes screw pump was back up and running within the 24-hour deadline. Water processing could continue as usual, reducing stress on other assets.

Alan continues: “Water authorities choose us to carry out emergency repairs because of our 24/7 service. We have engineers who will work through the night to complete repairs, ensuring that equipment can be back up and running as fast as possible. This is important in ensuring vital infrastructure can stay operational – so we have built our motor, pump and transmission services around a rapid response and repair turnaround.”