Local Timber Company – Conveyor System

Saving £££’s & Minimising Critical Plant Breakdown

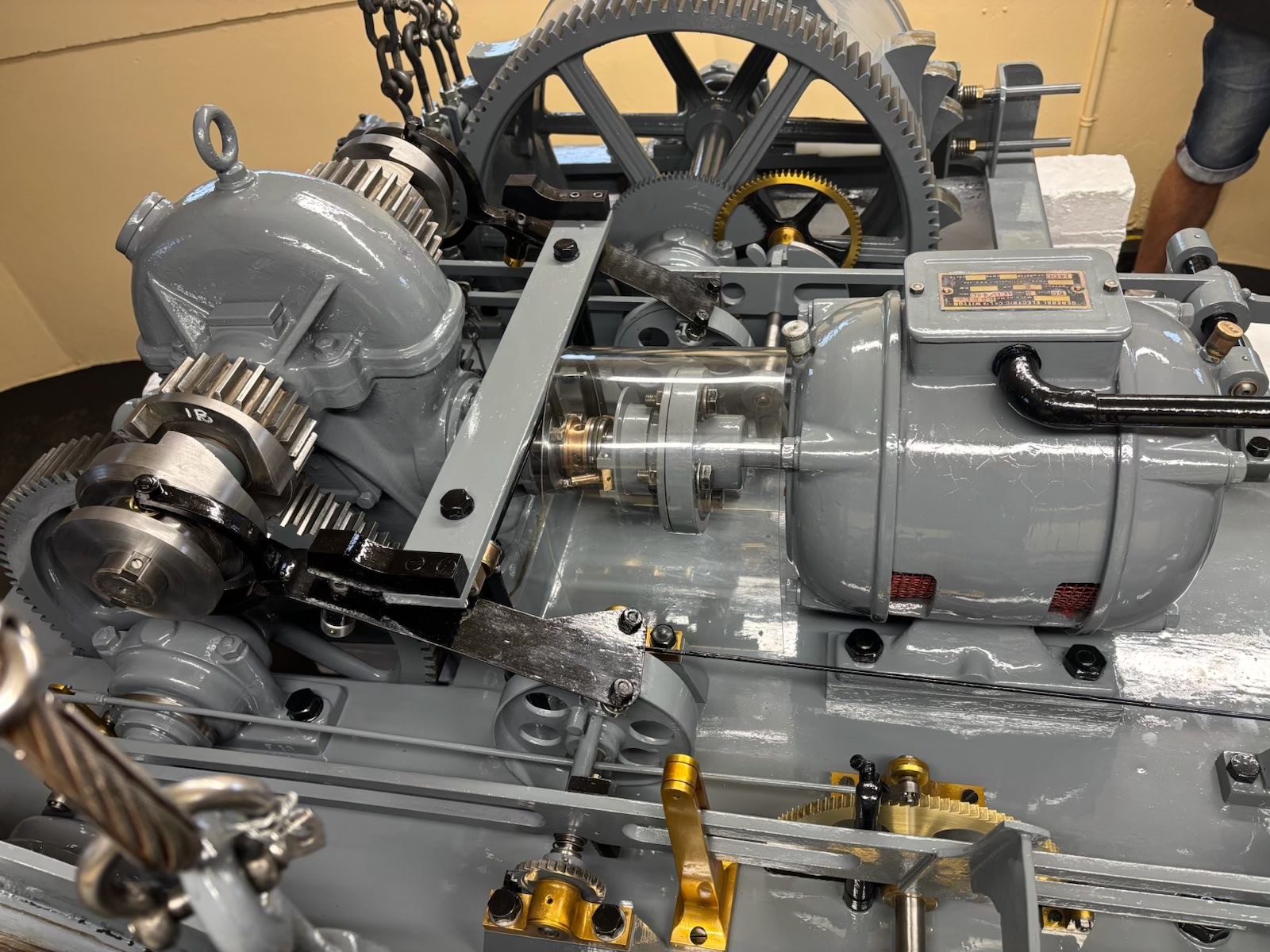

Our engineers were called to site to look at carrying out a routine maintenance job on our customers stacker conveyor. The machine is the customers main line which feeds blocks of wood which then go through a transfer conveyor and into the saw shop to be pre-cut into various lengths. Without this line running the rest of the lines do not run as they all feed off the stacker line.

Upon arriving on site to view the job before commencing the work, our engineers faced the problem of removing the main drive shaft from underneath the machine. Removing the shaft would be quite a process as accessibility was difficult and would mean stripping the machine down fully from both sides of the conveyor. The customer would need to allow for the line to be out of action for a whole day which would result in several thousand pounds in lost production.

Upon arriving on site to view the job before commencing the work, our engineers faced the problem of removing the main drive shaft from underneath the machine. Removing the shaft would be quite a process as accessibility was difficult and would mean stripping the machine down fully from both sides of the conveyor. The customer would need to allow for the line to be out of action for a whole day which would result in several thousand pounds in lost production.

Our team came up with the idea of cutting the main drive shaft into two sections and manufacturing an adjoining coupling complete with Tollok locking bushes for joining the two shafts together. This method would mean the machine would only need to be stripped from the one side only and the job completed in half the time meaning only half a days production would be lost which the customer was much happier with.

“I am extremely happy with the work carried out by Rotamec. Their engineers were very professional and the solution provided ensured production down time was an absolute minimum. The new design means that any future service will be made a lot easier which is a great help. The service we received was excellent from start to finish and the advice we received was excellent” Maintenance Manager